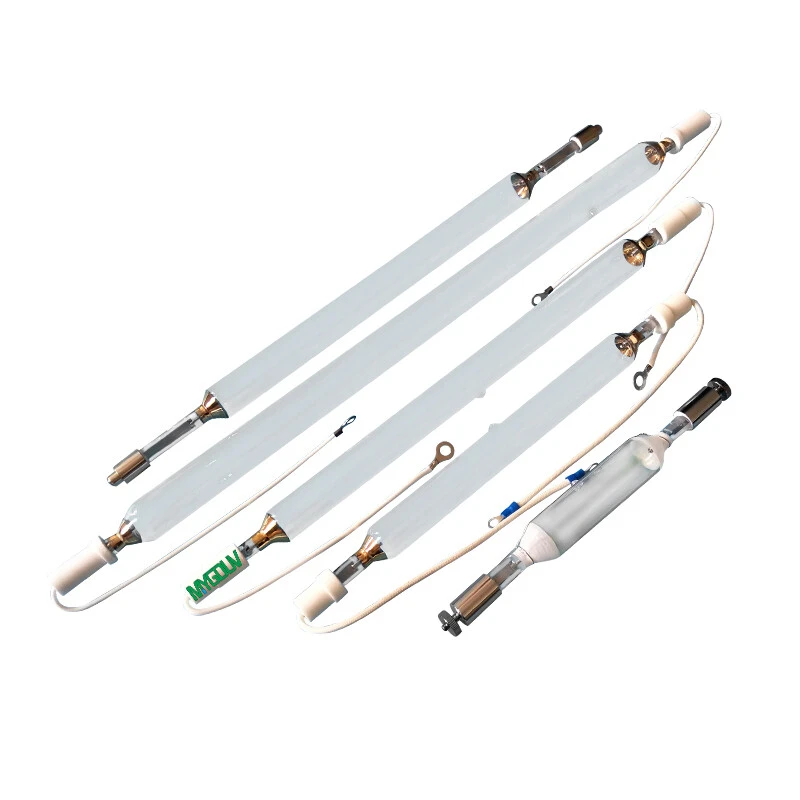

Introducing Customizable Shaped Infrared Heating Tubes: Efficiency Meets Versatility

In the world of industrial heating solutions, shaped infrared heating tubes offer a unique and highly efficient way to meet diverse heating needs. Whether you require heating for plastic parts, drying coatings, or other specialized applications, these tubes are designed to deliver precise and rapid heat where it’s needed most.

Key Features and Benefits

-

High Efficiency and Rapid Heating

Shaped infrared heating tubes are engineered to convert nearly 100% of their electrical energy into heat, making them significantly more efficient than traditional heating methods. This high efficiency not only reduces energy consumption but also ensures rapid heating and cooling cycles, with some models reaching operational temperatures in just 5-10 seconds. -

Customizable Designs

These tubes can be manufactured in various shapes and sizes to fit specific industrial requirements. Whether you need a straight tube, a U-shaped design, or even more complex geometries, custom options are available to optimize heat distribution and fit seamlessly into your production setup. -

Targeted Heating

Shaped infrared heating tubes are designed to emit heat directly onto the target material, minimizing energy loss and ensuring that heat is applied precisely where it is needed. This targeted approach is particularly beneficial for applications requiring high precision and efficiency. -

Durability and Longevity

Made from high-quality materials such as quartz and stainless steel, these tubes are built to withstand harsh industrial environments. Their robust construction ensures long-term reliability and reduced maintenance costs. -

Energy Savings

By directly heating objects rather than the surrounding air, shaped infrared heating tubes significantly reduce energy waste. This not only lowers operational costs but also contributes to a more sustainable production process.

Applications Across Industries

-

Plastic Processing: Ideal for heating plastic parts and molds, ensuring even heating and reducing production times.

-

Coating and Drying: Used for the rapid drying of paints, inks, and adhesives in industries such as automotive, printing, and electronics.

-

Food Processing: Efficient for drying and heating food products, maintaining product quality while reducing energy use.

-

Medical and Laboratory Applications: Used in medical devices for safe and effective thermal therapy.

Conclusion

Shaped infrared heating tubes offer a powerful, efficient, and versatile solution for a wide range of industrial heating needs. Their high efficiency, rapid heating capabilities, and customizable designs make them an ideal choice for enhancing productivity and reducing energy consumption. Invest in shaped infrared heating tubes to optimize your heating processes and achieve superior results.