Discover the Versatility and Strength of Flanged Pipe Systems

In the world of industrial and commercial piping, flanged pipes and their components play a crucial role in ensuring reliable and efficient fluid transportation. Whether you're working in the oil and gas industry, chemical processing, or even in building infrastructure, flanged pipes offer unmatched durability, flexibility, and ease of maintenance.

What Are Flanged Heaters?

Flanged pipes are designed with flanges—flat or raised rims that provide structural support and facilitate easy connection to other pipes, valves, or equipment. These flanges are typically secured with bolts and gaskets to create a tight seal, ensuring that the system remains leak-free even under high pressure.

Key Features and Benefits

-

High Pressure and Temperature Resistance

Flanged pipes are engineered to withstand extreme conditions. Made from materials like carbon steel, stainless steel, and alloy steel, they can handle high pressures and temperatures, making them ideal for demanding industrial applications. -

Ease of Installation and Maintenance

One of the standout features of flanged pipes is their ease of installation. The flange design allows for quick and secure connections, simplifying the assembly process. Additionally, flanged pipes can be easily disassembled for maintenance or repair, minimizing downtime. -

Versatility Across Industries

Flanged pipes are incredibly versatile and are used across a wide range of industries. They are commonly found in:-

Oil and Gas: For transporting crude oil, natural gas, and refined products.

-

Chemical Processing: To handle corrosive chemicals and ensure safe fluid transfer.

-

Power Generation: In steam and water systems within power plants.

-

Marine and Offshore: For critical applications in ships and offshore platforms.

-

-

Standardized and Compatible

Flanged pipes adhere to international standards such as ANSI, ASME, and DIN, ensuring compatibility with a wide range of components from different manufacturers. -

Durability and Longevity

The robust construction of flanged pipes ensures long-term reliability. High-quality materials and precision manufacturing processes result in components that can withstand harsh environments and repeated use.

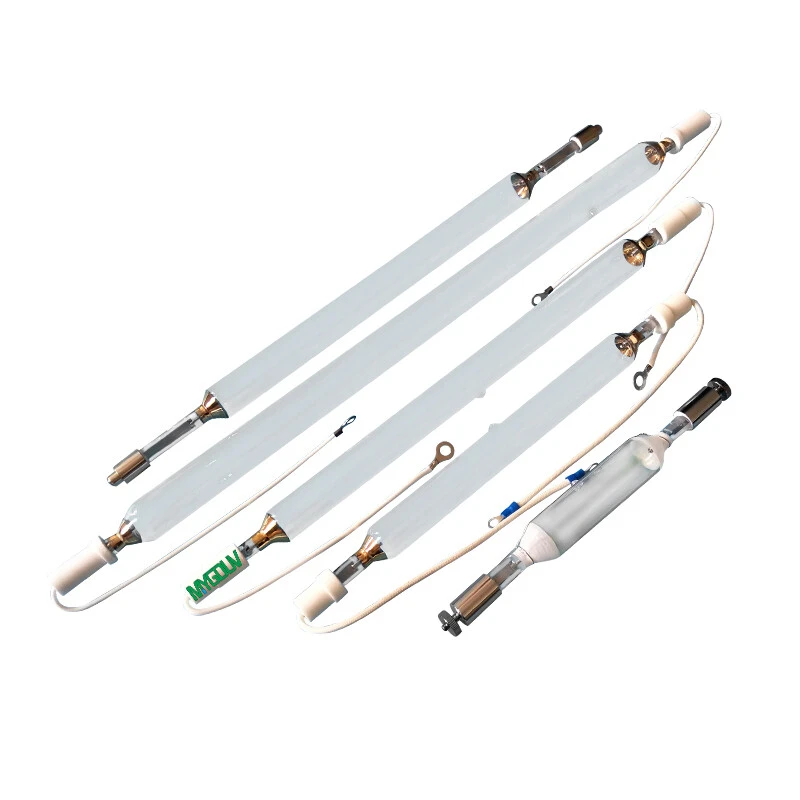

Types of Flanged Heater

Flanged pipes come in various types to meet specific needs:

-

Slip-On Flanges: Easy to install and suitable for low to moderate pressure applications.

-

Welding Neck Flanges: Provide enhanced strength and are ideal for high-pressure systems.

-

Threaded Flanges: Offer a secure connection without welding, making them perfect for applications where welding is not feasible.

-

Blind Flanges: Used to block off pipe ends or create dead ends in a piping system.

Conclusion

Flanged tubular heaterare essential components in modern industrial and commercial piping systems. Their ability to handle high pressures and temperatures, combined with ease of installation and maintenance, makes them a reliable choice for a wide range of applications. Invest in flanged pipes to ensure the efficiency, safety, and longevity of your fluid transportation systems.