Discover the Power of UV Curing Lamps: Efficiency, Quality, and Sustainability

In today's fast-paced industrial landscape, the need for efficient, high-quality, and environmentally friendly solutions has never been more critical. UV curing lamps offer a transformative technology that meets these demands head-on, providing rapid curing, enhanced product quality, and significant environmental benefits. Whether you're in manufacturing, printing, electronics, or any industry that requires precise and efficient curing processes, UV curing lamps are designed to revolutionize your operations.

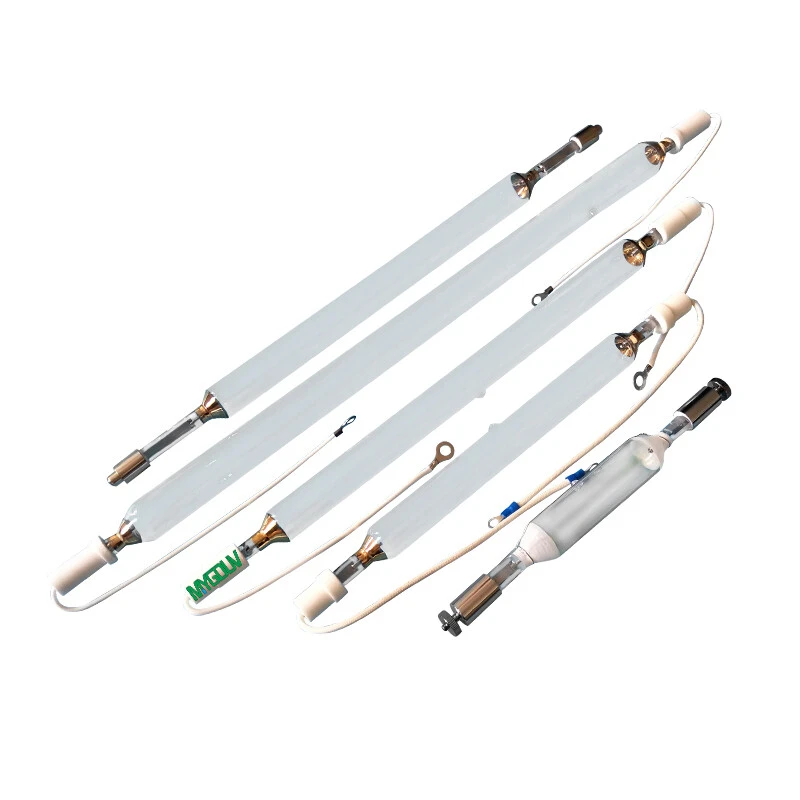

Key Features of UV Curing Lamps

-

Rapid Curing

UV curing lamps utilize ultraviolet light to quickly harden inks, adhesives, and coatings. This process, known as photopolymerization, occurs almost instantaneously, reducing curing times from hours to seconds. This rapid curing not only boosts productivity but also allows businesses to meet tight deadlines more effectively. -

Energy Efficiency

Unlike traditional thermal drying methods, UV curing lamps consume significantly less energy. The curing process is nearly instantaneous, meaning less energy is wasted during the drying phase. This not only leads to cost savings but also aligns with global sustainability goals. -

Superior Product Quality

UV curing technology results in higher quality products. The fast-drying characteristic reduces the likelihood of dust or particle contamination, ensuring a smooth and flawless finish. UV-cured materials often exhibit greater scratch resistance, increased chemical resistance, and more vibrant coloration. -

Environmentally Friendly

UV curing lamps produce minimal volatile organic compounds (VOCs) and do not require expensive solvent recovery systems. This makes UV curing a more environmentally friendly option, contributing to reduced air pollution and a smaller carbon footprint. -

Versatile Applications

UV curing lamps are used across a wide range of industries, including automotive, medical, electronics, printing, and more. They are ideal for curing inks, adhesives, coatings, and even for sterilizing medical equipment.

Applications Across Industries

-

Automotive: Used for curing paint and primer, reducing production time and increasing efficiency.

-

Medical: Employed for disinfecting medical equipment and instruments.

-

Printing: Ideal for drying ink and coatings on various materials like paper, cardboard, plastics, and fabrics.

-

Electronics: Used to cure protective coatings on electronic devices, enhancing durability.

-

Optical: Utilized in optical fibers for protection against decomposition.

Future Trends and Innovations

The future of UV curing technology is promising, with advancements in LED UV lamps, lower temperature ‘Cool Cure’ UV technology, and software innovations that optimize curing processes. These advancements are set to enhance operational efficiencies and sustainability benefits across different sectors.

Conclusion

UV curing lamps offer a powerful, efficient, and eco-friendly solution for a wide range of industrial applications. Their rapid curing capabilities, energy efficiency, and superior product quality make them an ideal choice for businesses looking to enhance their operations and reduce their environmental impact. Invest in UV curing technology today to unlock the benefits of this transformative technology and stay ahead in your industry.